Multi-level Production Planning, Capacity Plan

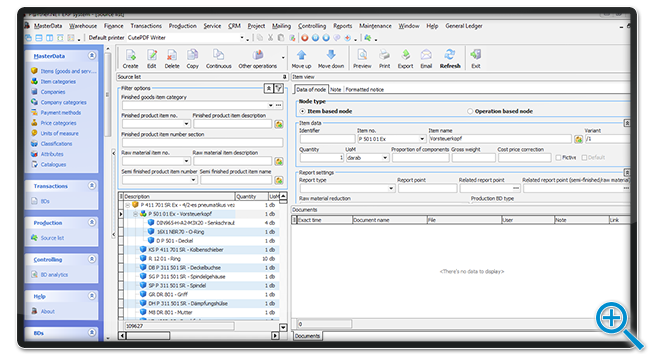

By dividing production planning into several phases, it becomes possible to estimate needed capacities and cooperation requirements in advance. Design surfaces provide the opportunity to obtain information about possible alternatives. Functions are designed to ensure that production be flexible and adequate resources are always optimally available. One of the biggest advantages of planning is the ability to calculate data in any direction (back and forth). Starting points may be determined to calculate the requirements of any component (machine time, human resources, material disposition, etc.).

Coarse-scale and fine-scale planning levels optimize human resources in production, as well as aiding in accurate procurement (labor, raw materials, tools). Due to the uniqueness of each manufacturing company and individual technology, production is always custom-designed.

With appropriate parameter settings, capacities can be anticipated up to a year in advance. In the case of other production methods, the management of daily ad hoc production also becomes easier.

The sellers see the estimate at the time of the proposal and, within a short time, can accurately calculate the manufacturing costs, as well as the expected margin, collateral and profit.